Manufacturing

What are the benefits of a circular manufacturing sector?

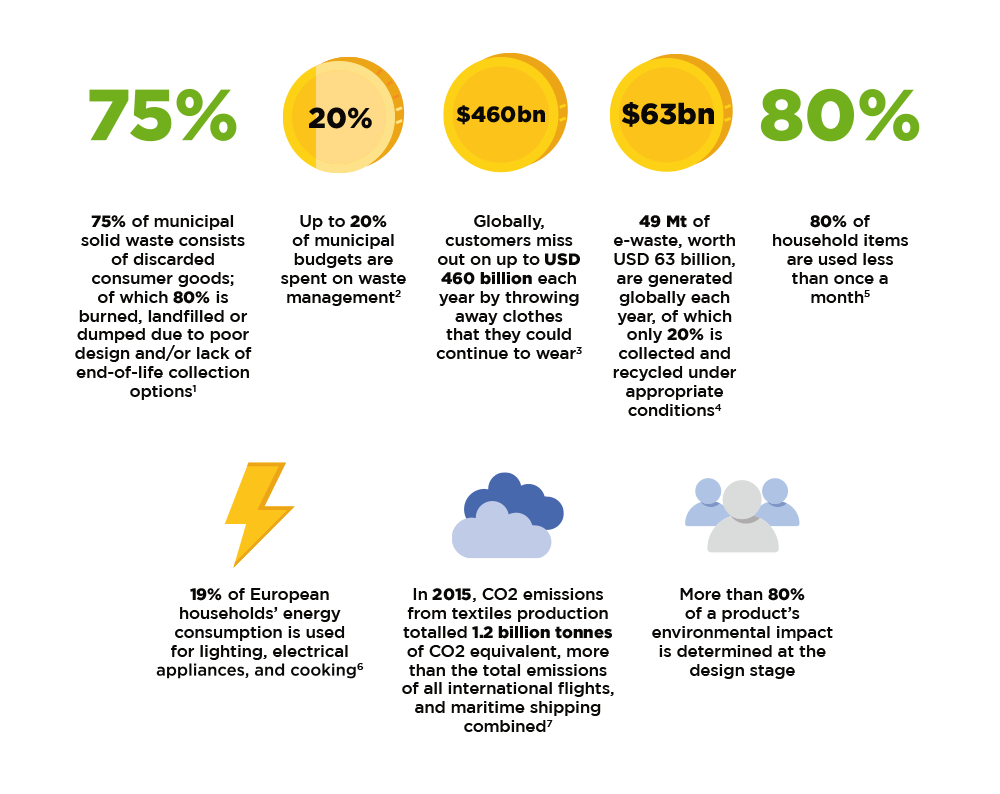

Manufacturing was once the core of the urban economy. In the last fifty years, however, manufacturing has to a large extent moved out of cities, and in some cases also out of the EU. The increasingly long and complex manufacturing value chains have been associated with an increased demand for depleting resources, high volumes of waste, and polluting emissions (see also figure 1)1,2. Technological developments and increasing consumption trends are expected to contribute further to these adverse effects. For example, waste from electrical and electronic equipment (WEEE) is already the fastest growing waste stream in the world.3

Figure 1. Examples of impact manufacturing has on the environment.

(Ellen Macarthur Foundation, 2019)

The transition to a circular manufacturing sector can break this negative cycle. For this to happen, circular economy principles need to be integrated into every stage of the manufacturing system.1 In this way, the manufacturing sector can, through improved product design and production, contribute to a reduction of virgin material consumption, reduction of waste and emissions, and economic benefits due to cost reduction and job creation.4

What will a circular manufacturing sector look like?

According to the Ellen MacArthur Foundation, the following changes are needed to move towards a circular manufacturing sector:5

- Materials should be kept in use while virgin material pressures should be reduced

- Production should occur locally and with a distributed production capacity

- Digital technology should be harnessed to simplify this process

How can we transform our manufacturing sector into a circular manufacturing sector?

Circular economy measures can be implemented in the different phases of the production process. Some examples are presented below.

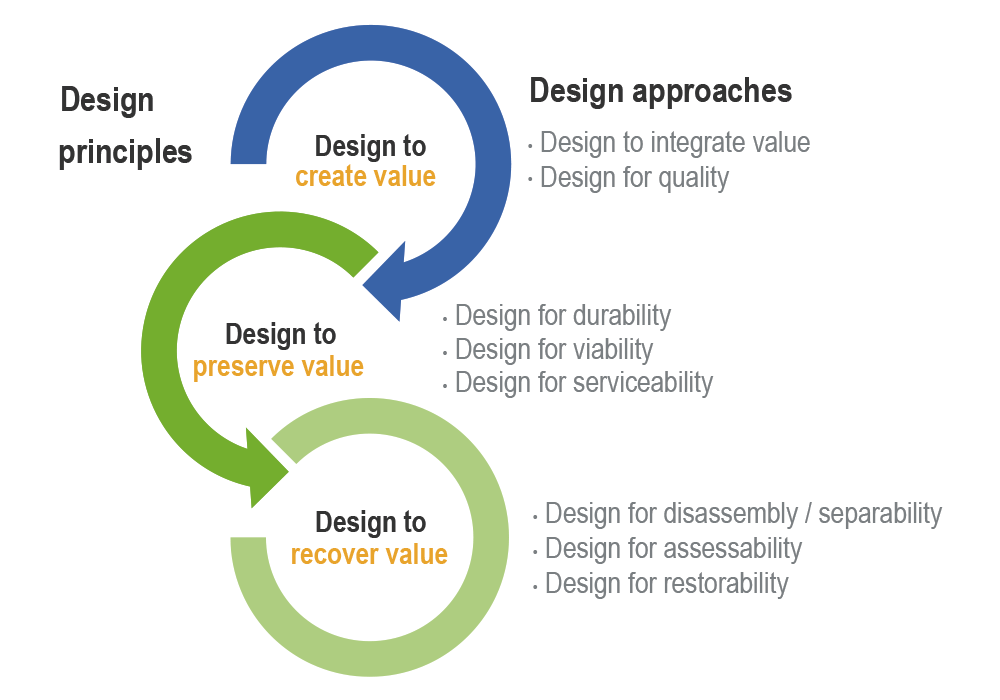

- Circular design models: decisions made in the design phase of manufacturing strongly influence the use- and after use-phase of a product. Ensuring that products are durable, easy to maintain, and can be recycled easily is therefore vital. A modular design contributes to the adaptability of the product and extends its life. Further circular design considerations are presented in figure 2 4. During the production process, circular economy principles can be integrated by increasing the use of secondary materials, by designing out waste, and by creating products on demand and on-site.5 Using locally abundant materials and technologies like 3D printing and robots for assembly can optimise this process.6 The creation of circular maker communities puts all these concepts into practice by focussing on local sustainable creation and repurposing. Currently, the cities of Leuven (Belgium), Istanbul (Turkey), Kaunas (Lithuania), Piraeus (Greece), Santander (Spain), Thessaloniki (Greece), and Venlo (Netherlands) experiment with the concept as a means to stimulate the circular economy in the context of a Horizon 2020 project.7

Figure 2. Different design approaches contribute to the circular economy in different ways.

(Un Environment, 2018)

- Use and life extension models: manufacturers can shift their business model from selling products to providing services under product-as-a-service contracts, where products are not bought but rented.8 Manufacturers can also facilitate the repair, remanufacturing, and re-sale of their products, to extend their life and reduce waste generation.1

- Value recovery models: when a product has reached its end of life, suitable infrastructure is needed to facilitate value recovery. This includes separate collection and, where needed, facilities for sorting and refinement of different material streams. Innovations in robotics, optical sorting, and artificial intelligence can improve the sorting and recovery of different types of materials.1 The concept of reverse logistics facilitates the return of end-of-life products for remanufacturing or recycling, and later reintegrating into new products.3 With the majority of waste being collected in cities, value recovery models also provide a strategy for the return of manufacturing in the urban economy. Innovative companies can use the collected and sorted waste streams as feedstock in their manufacturing processes. Prospering urban recycling hubs are feasible near waste treatment facilities that bring e.g. recycled plastics back into the economy.

- Circular support models: Recent developments in Information and Communication Technologies (ICT) can contribute to the success of many circular manufacturing models. The use of QR-codes and the Internet of Things simplify digital material banks and support repair and recycling by providing insight into the material composition of products.9 In addition, the availability of open-source circular designs can accelerate innovation by sharing best practices.1 In cities, the ‘urban mine’

concept is useful as it provides a good understanding of the material stocks and flows present in urban areas.2

concept is useful as it provides a good understanding of the material stocks and flows present in urban areas.2

References

-

1. Ellen MacArthur Foundation. (2019). Urban products system summary.

https://www.ellenmacarthurfoundation.org/assets/downloads/Products_All_Mar19.pdf -

2. Government of the Netherlands. (2016). A circular economy in the Netherlands by 2050.

https://www.government.nl/binaries/government/documents/policy-notes/2016/09/14/a-circular-economy-in-the-netherlands-by-2050/17037+Circulaire+Economie_EN.PDF

-

3. WBCSD. (2019). A new circular vision for electronics: Time for a global reboot.

https://www.wbcsd.org/Programs/Circular-Economy/Resources/A-New-Circular-Vision-for-Electronics -

4. UN Environment. (2018). Redefining Value – The Manufacturing Revolution.

https://www.resourcepanel.org/file/1105/download?token=LPqPM9Bo -

5. Ellen MacArthur Foundation & ARUP. (2019). Circular economy in cities: Project guide.

https://www.ellenmacarthurfoundation.org/assets/downloads/CE-in-Cities-Project-Guide_Mar19.pdf -

6. European Investment Bank. (2015). Assessment of access-to-finance conditions for projects supporting circular economy.

https://www.eib.org/attachments/pj/access_to_finance_study_on_circular_economy_en.pdf -

7. TU Delft. (2019). Pop-Machina.

https://www.tudelft.nl/bk/onderzoek/onderzoeksthemas/circular-built-environment/projects/pop-machina/ -

8. Rijksoverheid. (2018). De transitie naar een circulaire economie voor de maakindustrie.

https://www.rijksoverheid.nl/binaries/rijksoverheid/documenten/rapporten/2018/01/15/bijlage-6-transitieagenda-maakindustrie/bijlage-6-transitieagenda-maakindustrie.pdf -

9. European Environment Agency. (2017). Circular by design – Products in the circular economy.

https://circulareconomy.europa.eu/platform/sites/default/files/circular_by_design_-_products_in_the_circular_economy.pdf